Victrex® 450CA30 Granulado de PEEK de carbono

Want it by XYZ?

Need Help?

Our team are always happy to help!

Live Chat: Available from the bottom left of your screen.

Email:

sales@highperformancepolymer.com

Phone: +44(0)1865 684080

Instant Quote:

Submit a request for quote online by clicking the button below and a PDF quotation will be delivered to your inbox within 5 mins.

Material: PEEK

Measurement System: Metric

Colour: Black/Natural

Maximum Temperature: 260°C/500°F

Flammability: UL94 V-0

Victrex® 450CA30 Granulado de PEEK de carbono ajustarse a las siguientes Normas/Normas:

Granulado Victrex® PEEK CA30 (30 % de poliéter éter cetona reforzado con carbono) en stock en forma granular.

- Disponible en varios pesos

PEEK CA30 (poliéter éter cetona con un 30 % de fibra de carbono) es un compuesto termoplástico de alto rendimiento que combina las propiedades inherentes del PEEK con el refuerzo de las fibras de carbono. La adición de fibras de carbono mejora ciertas características del PEEK, lo que lo hace adecuado para aplicaciones exigentes que requieren alta resistencia, rigidez y resistencia al desgaste.

Características y aplicaciones principales de los gránulos PEEK CA30:

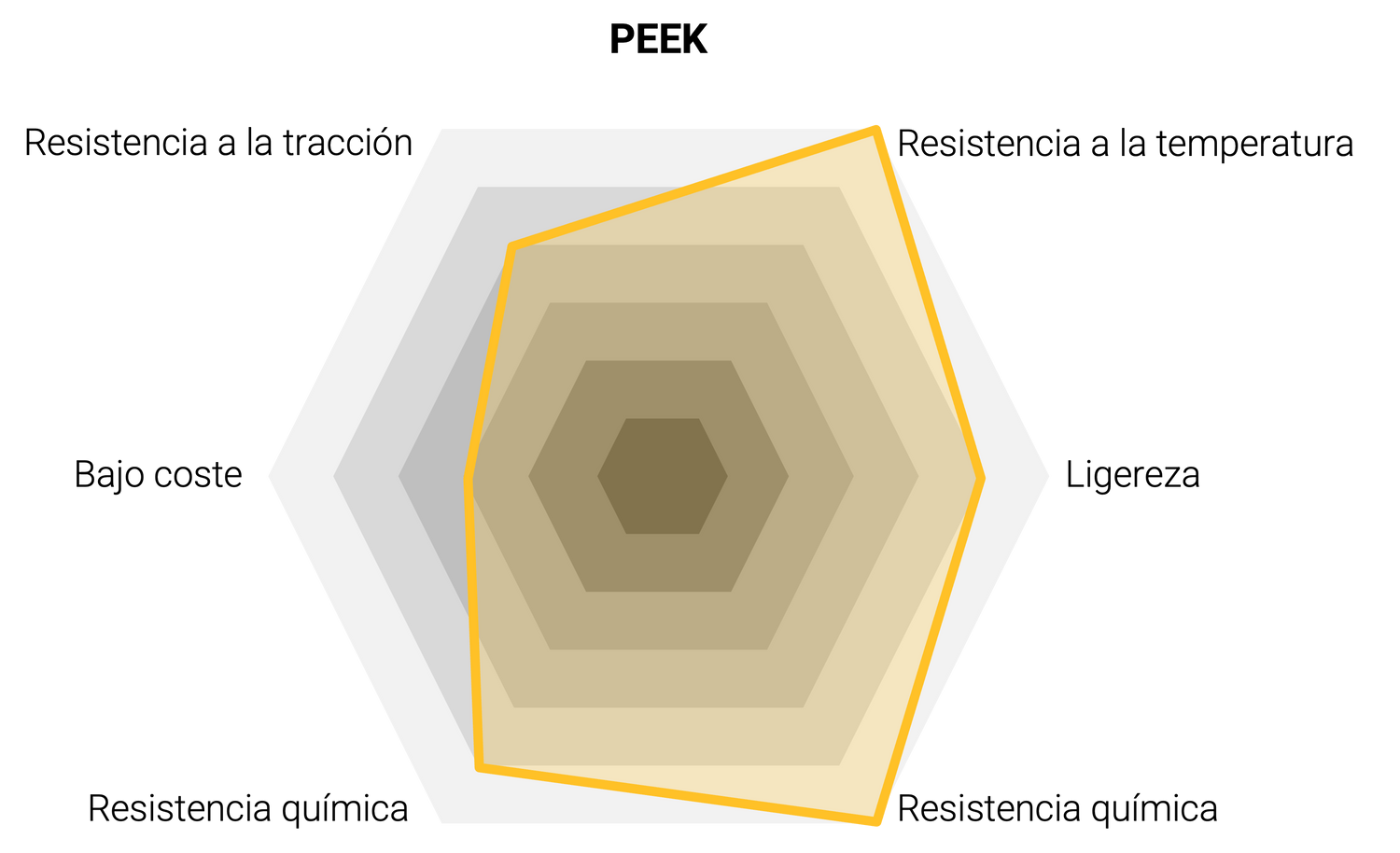

Resistencia mecánica: La inclusión de fibras de carbono mejora significativamente las propiedades mecánicas del PEEK CA30. Ofrece una alta resistencia a la tracción, rigidez y resistencia al impacto, lo que lo hace adecuado para componentes estructurales en diversas industrias.

Resistencia al desgaste: El refuerzo con fibras de carbono mejora la resistencia del material al desgaste y la abrasión, lo que hace que el PEEK CA30 sea adecuado para aplicaciones en las que las piezas están sometidas a fricción y tensión mecánica.

Estabilidad térmica: El PEEK es conocido por su excelente estabilidad térmica, y la adición de fibras de carbono no suele comprometer esta propiedad. El PEEK CA30 puede soportar altas temperaturas, lo que lo hace adecuado para aplicaciones en entornos con temperaturas elevadas.

Resistencia química: Al igual que el PEEK puro, el PEEK CA30 presenta una excelente resistencia química a una amplia gama de productos químicos y disolventes agresivos.

Conductividad eléctrica: La presencia de fibras de carbono proporciona al PEEK CA30 cierto nivel de conductividad eléctrica. Esto puede ser ventajoso en aplicaciones en las que se requiere disipación estática o conductividad eléctrica.

Aplicaciones:

El PEEK CA30 se utiliza habitualmente en aplicaciones aeroespaciales, automovilísticas, petroleras y gasísticas, médicas e industriales. Es adecuado para componentes como engranajes, cojinetes, piezas de bombas y componentes estructurales en condiciones de funcionamiento adversas.

Procesamiento de gránulos de PEEK CA30:

Cuando se utilizan gránulos de PEEK CA30, es esencial seguir las directrices del fabricante para su procesamiento. A continuación se describen los pasos generales para el procesamiento de los gránulos de PEEK CA30:

Secado: El PEEK es higroscópico, lo que significa que puede absorber la humedad del ambiente. Es fundamental secar los gránulos antes de procesarlos para evitar problemas como la porosidad en el producto final.

Extrusión o moldeo por inyección: El PEEK CA30 se puede procesar mediante técnicas como la extrusión o el moldeo por inyección. La elección depende de los requisitos específicos del producto final.

Temperatura del molde: Mantener la temperatura adecuada del molde es esencial para conseguir las propiedades mecánicas y el acabado superficial deseados.

Enfriamiento: El enfriamiento adecuado de la pieza moldeada es fundamental para garantizar la estabilidad dimensional y evitar deformaciones.

Consulte siempre las fichas técnicas y las directrices de procesamiento de Victrex® para obtener recomendaciones específicas sobre perfiles de temperatura, diseño de moldes y otros parámetros de procesamiento. De este modo, se garantiza que el material se procesa correctamente y que los componentes finales cumplen los criterios de rendimiento deseados.

La ficha técnica de PEEK puede descargarse en formato PDF.

Devuelva los componentes en un plazo de 90 días para obtener un reembolso completo. Consulte las condiciones de devolución para obtener más información.

Polyether Ether Ketone (PEEK) Ficha de datos

Siga el enlace siguiente para consultar nuestra hoja de datos PEEK . Incluye propiedades como la resistencia mecánica, eléctrica, térmica y química.

Custom Manufacturing

Can't find a component?

We can manufacture components to your specification in any of our performance polymer materials. Click on the link, fill out a short form and you'll receive a competitive, no obligation quote within 24 hours.

PEEK Propiedades clave

¿Por qué elegir polímeros de alto rendimiento?

-

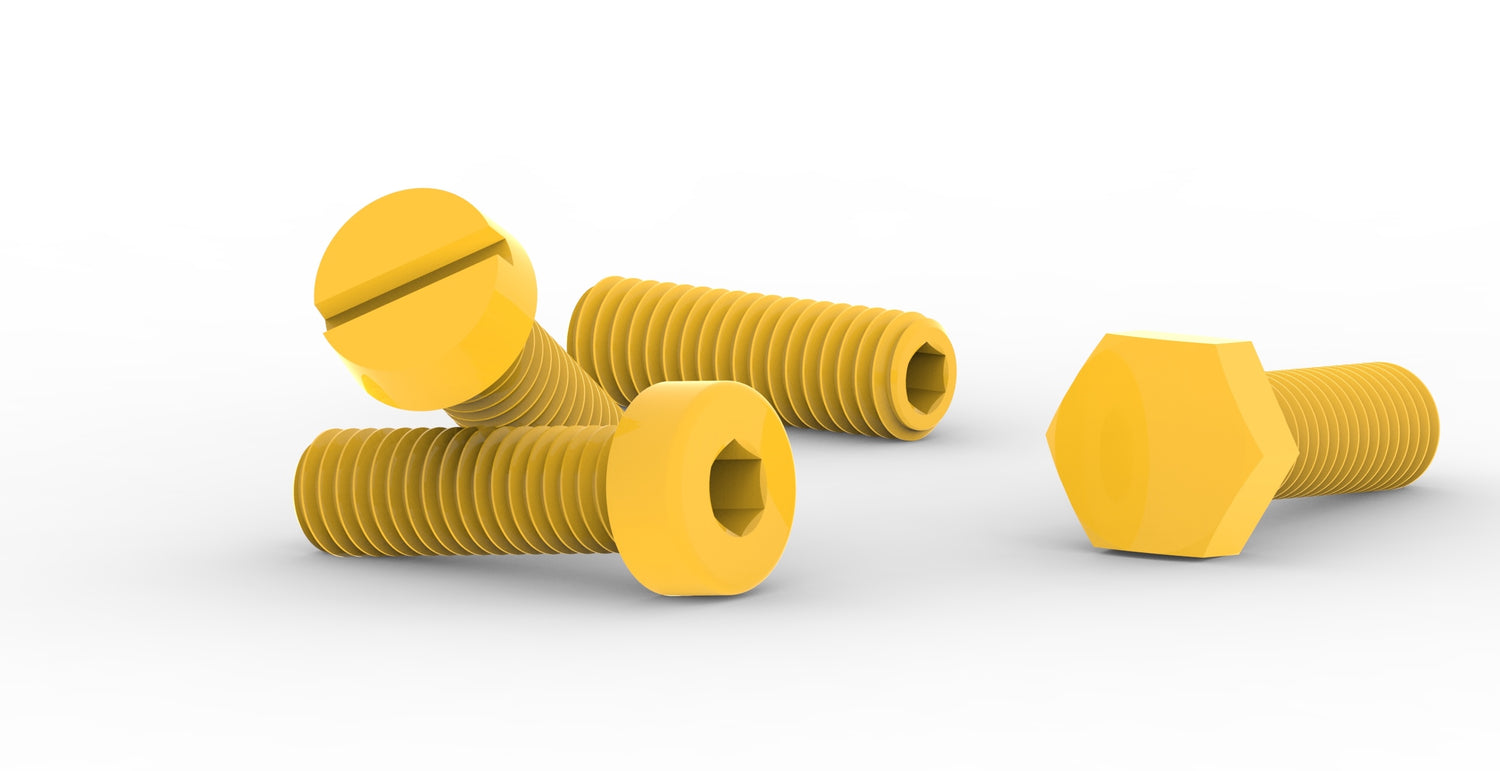

Más de 50.000 fijaciones en stock

No hay plazos de entrega largos. Tenemos una amplia gama de fijaciones PEEK disponibles para entrega urgente (se envían el mismo día si se piden antes de las 3 de la tarde de lunes a jueves).

Las fijaciones no disponibles para entrega urgente mostrarán la fecha de entrega prevista encima del botón 'añadir al carrito'.

Distribuidor directo del fabricanteSomos un distribuidor directo del fabricante, esto nos permite garantizar precios altamente competitivos y mantener nuestros estantes abastecidos. Todos nuestros productos se fabrican con los más altos estándares y presentan características excepcionales.

Certificado ISO9001Certificado a través de Quality Veritas. High Performance Polymer cumple con el sistema de gestión de calidad ISO9001. Certificados disponibles previa solicitud.

-

Certificados de materiales

Ofrecemos una trazabilidad completa de los materiales y podemos proporcionar certificados que confirmen los datos de los materiales y el número de lote, que pueden rastrearse hasta el fabricante.

Certificado de conformidadTambién proporcionamos un certificado de conformidad a petición, confirmando la norma de fabricación del producto y el material.