200 Productos

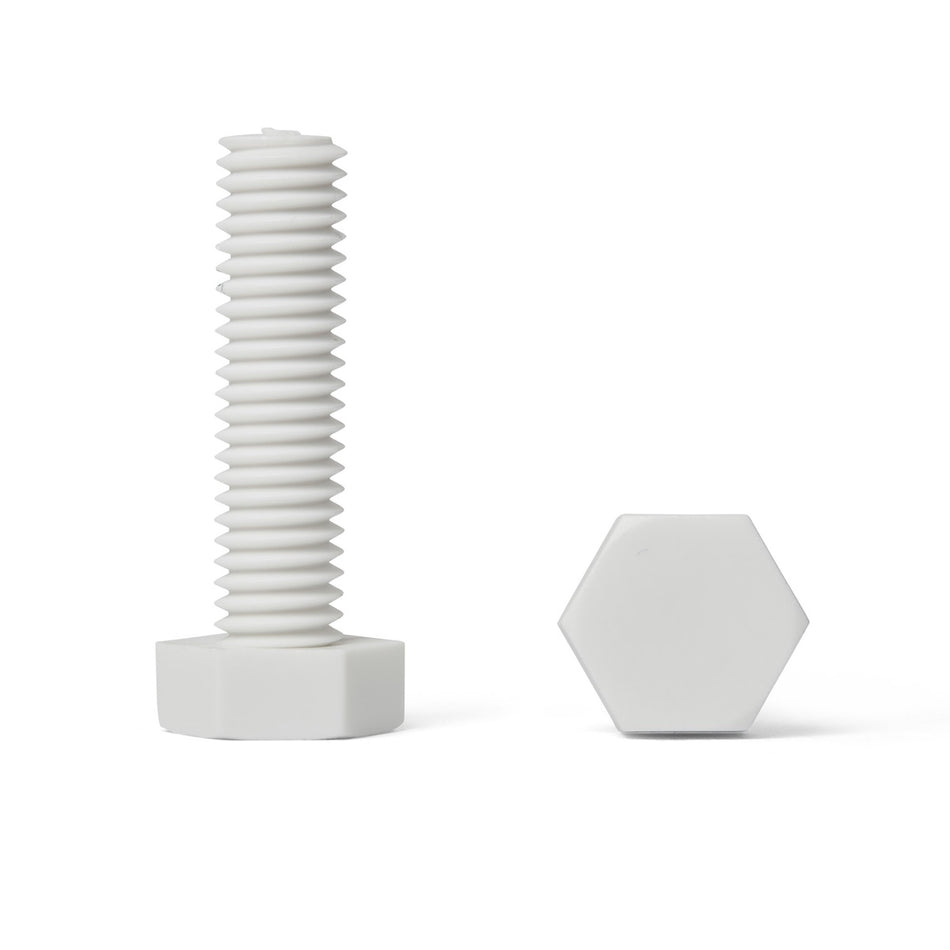

Tornillos, tuercas, pernos, arandelas y fijaciones resistentes a productos químicos

Why Are Chemical Resistant Fasteners Needed?

Chemical resistant screws, nuts, bolts, washers, and fasteners are an important component in many applications where chemical exposure is a concern, and they can help to extend the service life of fasteners and improve the reliability of equipment and structures in chemically challenging environments.

Chemical Resistant Polymer Fasteners

Chemical resistant polymer fasteners are a type of fastener that is made from polymers, or plastic materials, that are resistant to chemical corrosion. These are used in a wide range of applications where exposure to chemicals could be a problem, and they offer several benefits over traditional metallic fasteners.

One of the main benefits of chemical resistant polymer fasteners is their lightweight and easy-to-handle properties. This makes them particularly suitable for use in applications where weight is a concern, such as in the aerospace and automotive industries. Polymer fasteners are also typically easier to install than metal equivalents, as they do not require specialized tools or equipment.

In addition to their lightweight and easy-to-handle properties, chemical resistant polymers offer good electrical insulation properties. This makes them suitable for use in electrical and electronic applications where electrical insulation is important.

There are several types of chemical resistant polymer fasteners, including polyetheretherketone (PEEK), polyvinyl chloride (PVC), and polyvinylidene fluoride (PVDF). PEEK fasteners are known for their excellent mechanical and thermal properties, as well as their resistance to a wide range of chemicals. PVC fasteners are also known for their good mechanical and thermal properties, as well as their resistance to UV light and weathering. PVDF fasteners are known for their excellent chemical resistance, making them suitable for use in corrosive environments.

What are chemical resistant fasteners used for?

Chemical-resistant fasteners are essential in industries where exposure to corrosive substances and harsh environments is frequent. They are widely used in chemical processing plants, refineries, and wastewater treatment facilities, where they ensure the integrity of equipment and structures by resisting degradation from acids, solvents, and other aggressive chemicals. These fasteners are also critical in the pharmaceutical and food industries, where maintaining hygiene and preventing contamination is crucial. In marine applications, chemical-resistant fasteners help prevent corrosion from saltwater, while in the aerospace and automotive sectors, they provide durable solutions for components exposed to extreme conditions.

What Are Chemical Resistant Fasteners?

Chemical resistant screws, nuts, bolts and washers are fasteners that are designed to resist the effects of chemical exposure. They are used in a variety of applications where chemical exposure is a concern, such as in the chemical or pharmaceutical industries, or in environments where corrosive substances are present.

Los tornillos, tuercas, pernos, arandelas y elementos de fijación químicamente resistentes son elementos de fijación diseñados para resistir los efectos de la exposición química. Se utilizan en diversas aplicaciones en las que la exposición a productos químicos es un problema, como en las industrias química o farmacéutica, o en entornos con presencia de sustancias corrosivas.

Hay varias formas de hacer que los elementos de fijación sean resistentes a los productos químicos, como el uso de materiales resistentes a los productos químicos y la aplicación de revestimientos resistentes a los productos químicos. Algunos de los materiales más comunes utilizados para los elementos de fijación resistentes a los productos químicos son el acero inoxidable, el latón y el bronce, así como determinados tipos de plástico o polímero. Estos materiales son resistentes a la corrosión y a otros tipos de degradación química debido a sus propiedades químicas inherentes, y a menudo se utilizan en entornos en los que la exposición química es un problema.

Además de utilizar materiales resistentes a los productos químicos, también se pueden aplicar revestimientos resistentes a los productos químicos a los elementos de fijación para proporcionar una capa adicional de protección contra la exposición a los productos químicos. Estos revestimientos pueden aplicarse mediante procesos como galvanoplastia, anodizado o pintura, y pueden ayudar a proteger el material subyacente de los efectos de la exposición química.

En general, los tornillos, tuercas, pernos, arandelas y elementos de fijación resistentes a los productos químicos son un componente importante en muchas aplicaciones en las que la exposición química es un problema, y pueden ayudar a prolongar la vida útil de los elementos de fijación y mejorar la fiabilidad de los equipos y estructuras en entornos químicamente difíciles.