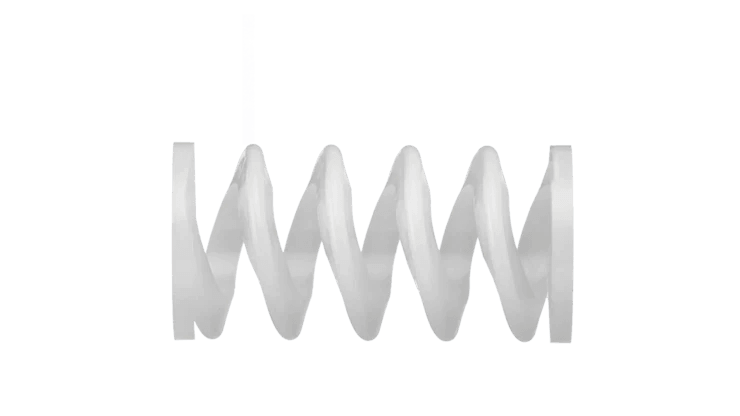

Polyacetal (POM) OMEGA Type Spring (19.5-24-36L)

Polyacetal (POM) OMEGA Type Spring (19.5-24-36L)

Descuentos por volumen disponibles:

Ver más Ver menos

Want it by XYZ?

Need Help?

Our team are always happy to help!

Live Chat: Available from the bottom left of your screen.

Email:

sales@highperformancepolymer.com

Phone: +44(0)1865 684080

Instant Quote:

Submit a request for quote online by clicking the button below and a PDF quotation will be delivered to your inbox within 5 mins.

Material: POM

Measurement System: Metric

Colour: White

Continuous use temperature: 95°C/203°F

Flammability: UL94 HB

Polyacetal (POM) OMEGA Type Spring (19.5-24-36L) ajustarse a las siguientes Normas/Normas:

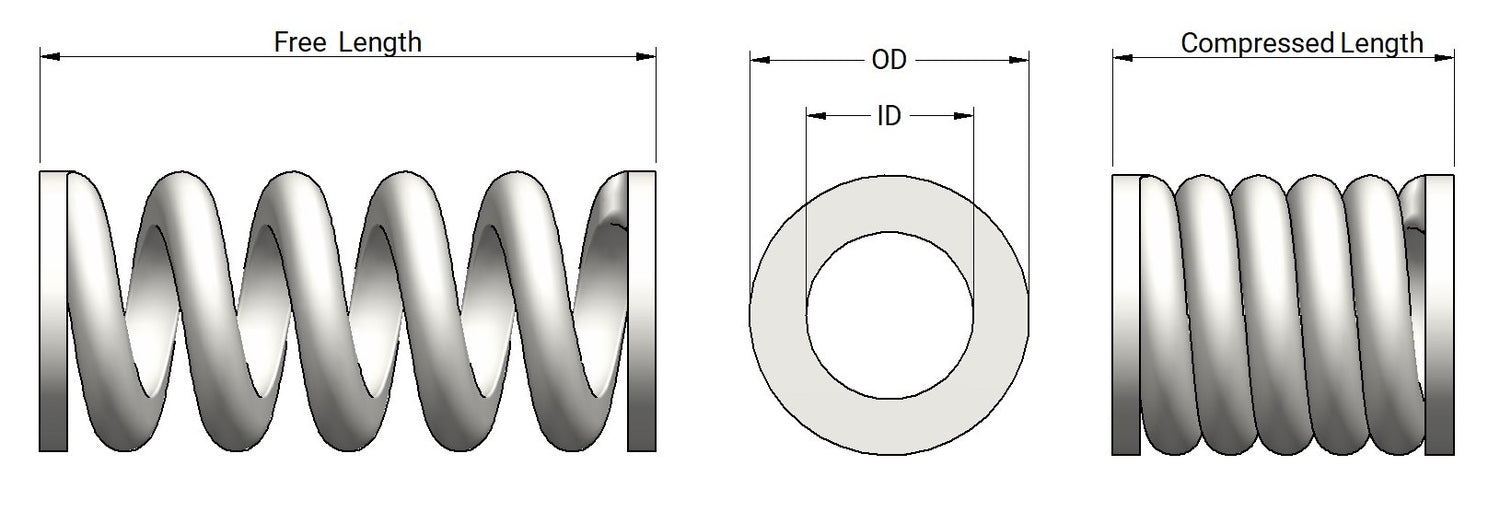

Polyacetal (POM) OMEGA Type Compression Springs, with an Inner Diameter of 19.5mm, an Outer Diameter of 24mm, and a Free Length of 36mm, is a component designed for applications requiring excellent mechanical properties, low friction, and high dimensional stability. POM, also known as acetal, is a highly crystalline thermoplastic known for its high strength, stiffness, and resistance to wear and abrasion. These springs are engineered to provide reliable compression and durability in various demanding environments, maintaining their performance and integrity across a wide range of temperatures and conditions.

Size:

Inner Diameter (mm) - 19.5mm

Outer Diameter (mm) - 24mm

Free Length (mm) - 36mm

Spring Rate (N/mm) – 0.59-0.96

Advantages of Using Polyacetal (POM) OMEGA Type Compression Springs:

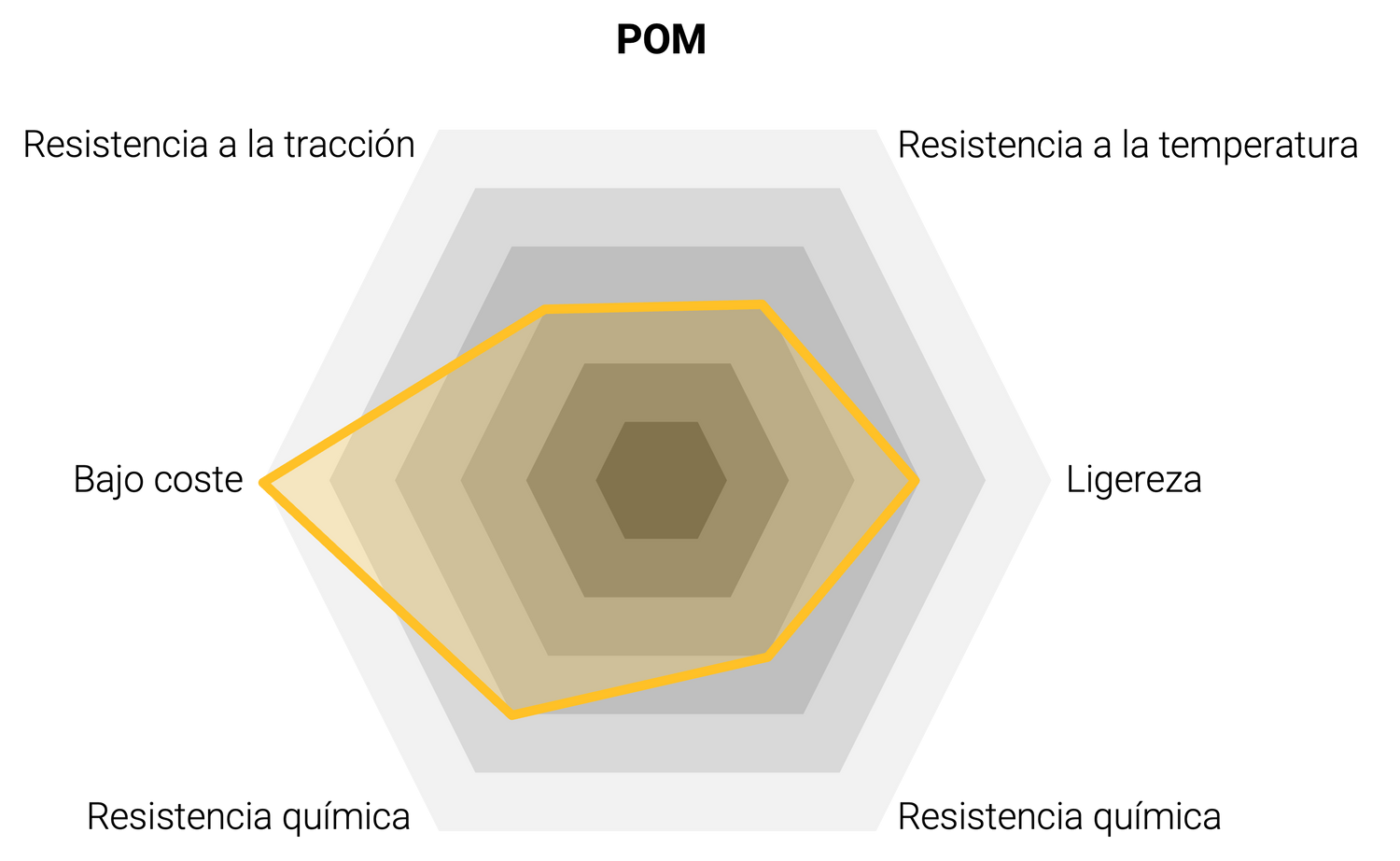

High Mechanical Strength: POM provides excellent tensile and compressive strength, ensuring robust performance under various loads.

Low Friction: The material's low friction coefficient reduces wear and improves efficiency in dynamic applications.

Dimensional Stability: POM offers high dimensional stability, maintaining its shape and mechanical properties over time and under varying conditions.

Wear and Abrasion Resistance: Excellent resistance to wear and abrasion, extending the lifespan of the springs and the components they interact with.

Chemical Resistance: Resistant to many solvents, fuels, and chemicals, making it suitable for use in corrosive environments.

Fatigue Resistance: POM exhibits good fatigue resistance, making it suitable for cyclic loading applications.

Low Moisture Absorption: The material absorbs minimal moisture, ensuring consistent performance in humid or wet environments.

Specific Applications of Polyacetal (POM) OMEGA Type Compression Springs:

Automotive Industry:

Used in various automotive components such as fuel systems, throttle valves, and interior mechanisms where high strength and low friction are required.

Consumer Electronics:

Applied in devices like printers, cameras, and other electronics where durability, precision, and smooth operation are critical.

Medical Devices:

Utilised in medical instruments and diagnostic equipment where high precision, dimensional stability, and resistance to wear are essential.

Ideal for components requiring consistent spring action and long-term reliability.

Industrial Machinery:

Employed in machinery and equipment that experience high wear and require robust components to maintain operational integrity.

Aerospace:

Used in aerospace applications where lightweight and high-strength materials are essential, such as in control systems and safety equipment.

Suitable for components exposed to varying environmental conditions.

Construction:

Applied in building materials and systems that require durable, wear-resistant components that can withstand outdoor exposure.

Plumbing and Fluid Handling:

Utilised in plumbing and fluid handling systems due to its chemical resistance and low moisture absorption.

Polyacetal (POM) OMEGA Type Compression Springs, with an Inner Diameter of 19.5mm, an Outer Diameter of 24mm, and a Free Length of 36mm, offer a robust and reliable solution for various demanding applications. These springs benefit from POM's high mechanical strength, low friction, dimensional stability, wear and abrasion resistance, chemical resistance, fatigue resistance, and low moisture absorption. Ideal for use in automotive, consumer electronics, medical devices, industrial machinery, aerospace, construction, and plumbing systems, these springs ensure long-lasting performance and reliability in critical environments.

La ficha técnica de POM puede descargarse en formato PDF.

Devuelva los componentes en un plazo de 90 días para obtener un reembolso completo. Consulte las condiciones de devolución para obtener más información.

| Inner Diameter (mm) | Outside Diameter (mm) | Free Length (mm) | Solid Height (mm) | Spring Rate (mm) |

| 19.5 | 24 | 36 | 18 | 0.59-0.96 |

Tabla de dimensiones

Las dimensiones de Polyacetal (POM) OMEGA Type Spring (19.5-24-36L) en todos los tamaños disponibles se muestran según el dibujo del producto anterior.

Key Polyacetal (POM) Properties

Polyacetal (POM) Ficha de datos

Siga el enlace siguiente para consultar nuestra hoja de datos POM . Incluye propiedades como la resistencia mecánica, eléctrica, térmica y química.

Custom Manufacturing

Can't find a component?

We can manufacture components to your specification in any of our performance polymer materials. Click on the link, fill out a short form and you'll receive a competitive, no obligation quote within 24 hours.

POM Propiedades clave

¿Por qué elegir polímeros de alto rendimiento?

-

Más de 50.000 fijaciones en stock

No hay plazos de entrega largos. Tenemos una amplia gama de fijaciones PEEK disponibles para entrega urgente (se envían el mismo día si se piden antes de las 3 de la tarde de lunes a jueves).

Las fijaciones no disponibles para entrega urgente mostrarán la fecha de entrega prevista encima del botón 'añadir al carrito'.

Distribuidor directo del fabricanteSomos un distribuidor directo del fabricante, esto nos permite garantizar precios altamente competitivos y mantener nuestros estantes abastecidos. Todos nuestros productos se fabrican con los más altos estándares y presentan características excepcionales.

Certificado ISO9001Certificado a través de Quality Veritas. High Performance Polymer cumple con el sistema de gestión de calidad ISO9001. Certificados disponibles previa solicitud.

-

Certificados de materiales

Ofrecemos una trazabilidad completa de los materiales y podemos proporcionar certificados que confirmen los datos de los materiales y el número de lote, que pueden rastrearse hasta el fabricante.

Certificado de conformidadTambién proporcionamos un certificado de conformidad a petición, confirmando la norma de fabricación del producto y el material.