PTFE/Teflon Coated A2-70 Stainless Steel Hexagon Nuts - DIN 934

PTFE/Teflon Coated A2-70 Stainless Steel Hexagon Nuts - DIN 934

Volume Discounts Available:

Want it by XYZ?

Need Help?

Our team are always happy to help!

Live Chat: Available from the bottom left of your screen.

Email:

sales@highperformancepolymer.com

Phone: +44(0)1865 684080

Instant Quote:

Submit a request for quote online by clicking the button below and a PDF quotation will be delivered to your inbox within 5 mins.

Material: PTFE Coated A2-70 Stainless Steel

Measurement System: Metric

Drive Type: Hexagon (External)

Colour: Blue

260°C

UL94 V0

PTFE/Teflon Coated A2-70 Stainless Steel Hexagon Nuts - DIN 934 conform to the following Standards/Norms:

ISO 4032

DIN 934

CSN 021401

PN 82144

UNI 5588

PTFE (Polytetrafluoroethylene) coated stainless steel nuts are essential fasteners known for their excellent corrosion resistance, non-stick properties, and wide temperature range suitability. These nuts are made of stainless steel and coated with a layer of PTFE, providing numerous advantages for various applications. Here's a comprehensive look at PTFE coated stainless steel nuts, their uses, benefits, and available sizes.

Our PTFE Hexagon Nuts are compliant to DIN 934 specification.

PTFE Datasheet available below.

If further information is required, please contact us.

What are PTFE Hexagon Nuts?

Advantages of PTFE Coated Stainless Steel Nuts:

-

Corrosion Resistance: Stainless steel nuts already possess inherent corrosion resistance, and the PTFE coating further enhances their ability to withstand harsh environments, chemicals, and atmospheric conditions.

-

Non-Stick Properties: PTFE is renowned for its non-stick nature, reducing the likelihood of galling, seizing, or sticking during assembly or disassembly.

-

Low Friction: The PTFE coating reduces friction between the nut and the mating threads or surfaces, making them easier to install and remove.

-

Chemical Inertness: PTFE coated stainless steel nuts exhibit high chemical inertness, making them suitable for use in aggressive chemical environments without risk of corrosion or degradation.

-

Temperature Range: PTFE can withstand a broad temperature range, ensuring stability and reliability in both high-temperature and cryogenic applications.

-

Electrical Insulation: PTFE coated nuts provide electrical insulation, making them suitable for electrical and electronic applications.

Uses of PTFE Coated Stainless Steel Nuts:

-

Food and Beverage Industry: PTFE coated stainless steel nuts find extensive use in the food and beverage industry, especially in equipment where hygiene and corrosion resistance are crucial.

-

Chemical Processing: These nuts are commonly used in chemical plants and laboratories where resistance to corrosive chemicals is essential.

-

Marine and Offshore: PTFE coated nuts are highly resistant to saltwater and are used in marine and offshore applications, including shipbuilding and marine equipment.

-

Aerospace: The aerospace industry benefits from PTFE coated nuts in components requiring resistance to corrosion and low friction, such as aircraft assembly and maintenance.

-

Pharmaceutical: PTFE coated stainless steel nuts are employed in pharmaceutical processing equipment due to their hygienic and non-reactive nature.

-

Oil and Gas: In the oil and gas industry, PTFE coated nuts are used in equipment and pipelines to withstand corrosive fluids and high-pressure environments.

-

Electronics and Electrical: PTFE coated stainless steel nuts are employed in electrical and electronic equipment where electrical insulation and non-conductivity are vital.

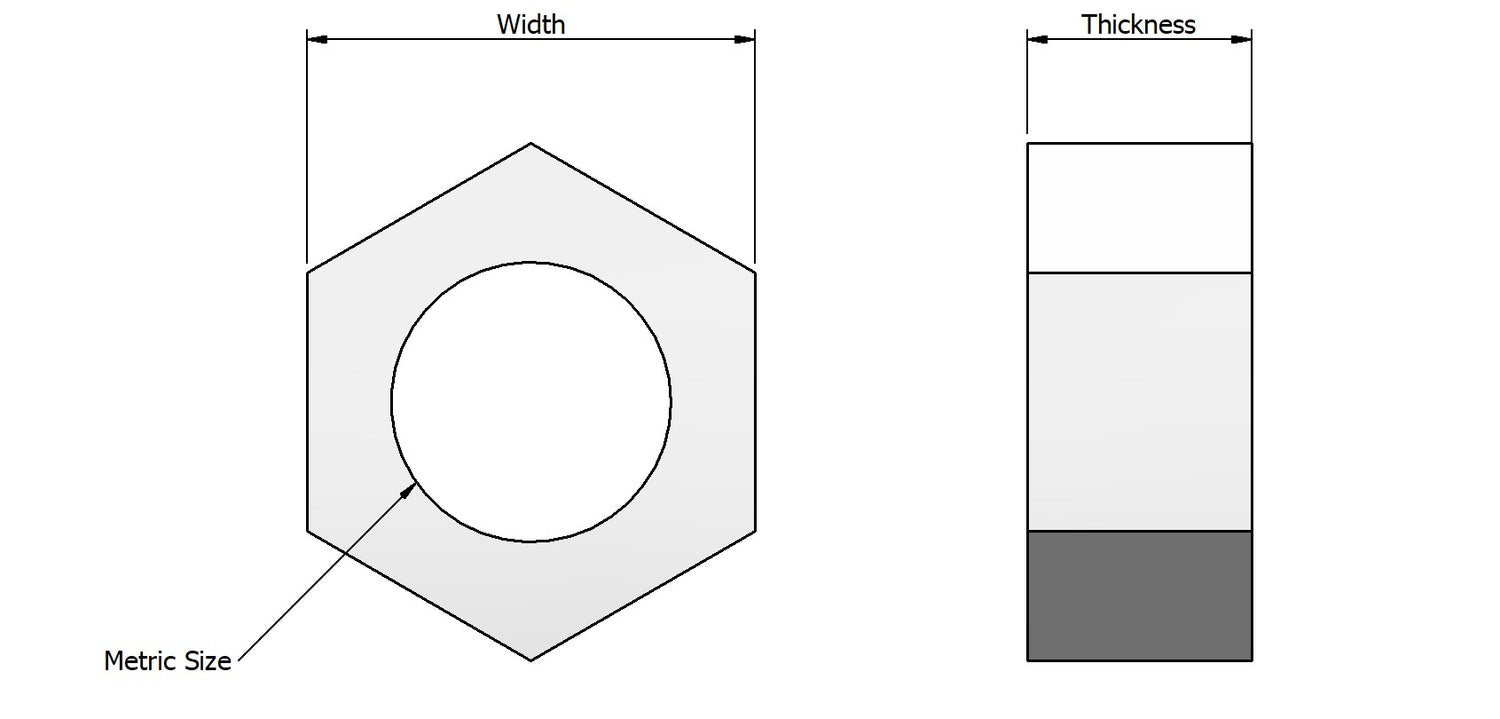

Sizes of PTFE Coated Stainless Steel Nuts:

PTFE coated stainless steel nuts are available in various sizes to accommodate different applications. The most common sizes include M4, M5, M6, M8, M10, M12, and M16. The nuts are available in different thread types, including metric, UNC (Unified National Coarse), and UNF (Unified National Fine).

Choosing the appropriate size of PTFE coated stainless steel nut depends on factors such as the specific application, the mating bolt or stud size, load requirements, and environmental conditions. Ensuring that the nut size matches the corresponding bolt or stud is crucial for proper assembly and secure fastening.

PTFE coated stainless steel nuts offer numerous advantages, including corrosion resistance, non-stick properties, low friction, chemical inertness, wide temperature range suitability, and electrical insulation. These qualities make them well-suited for use in various industries, including food and beverage, chemical processing, marine, aerospace, pharmaceutical, oil and gas, electronics, and electrical. Available in different sizes and thread types, PTFE coated stainless steel nuts can be tailored to specific application requirements, ensuring reliable and long-lasting performance in demanding environments.

The PTFE Coated A2-70 Stainless Steel data sheet is available as a PDF to download below.

Return components within 90 days for a full refund. Please see returns terms and conditions for further information.

PTFE Coated A2-70 Stainless Steel Datasheet

Follow the link below to view our PTFE Coated A2-70 Stainless Steel data sheet. This includes properties such as mechanical, electrical, thermal and chemical resistance.

Custom Manufacturing

Can't find a component?

We can manufacture components to your specification in any of our performance polymer materials. Click on the link, fill out a short form and you'll receive a competitive, no obligation quote within 24 hours.

PTFE Coated A2-70 Stainless Steel Key Properties

Why Choose High Performance Polymer?

-

50,000+ Fasteners In stock

No long lead times. We have a large range of PEEK fasteners available for express delivery (Dispatched the same day if ordered before 3PM Monday-Thursday).

Fasteners not available for express delivery will display the expected delivery date above the 'add to cart' button.

Manufacturer Direct DistributorWe are a manufacturer direct distributor, this allows us to ensure highly competitive prices and keep our shelves stocked. All of our products are manufactured to the highest standards and exhibit exceptional characteristics.

ISO9001 CertifiedCertified through Quality Veritas. High Performance Polymer conforms to the ISO9001 quality management system. Certificates available on request.

-

Material Certificates

We provide full material traceability and can provide certification confirming material data and batch number, which can be traced back to the manufacturer.

Certificate Of ConformityWe also provide a certificate of conformity on request, confirming the product manufacturing standard and material.