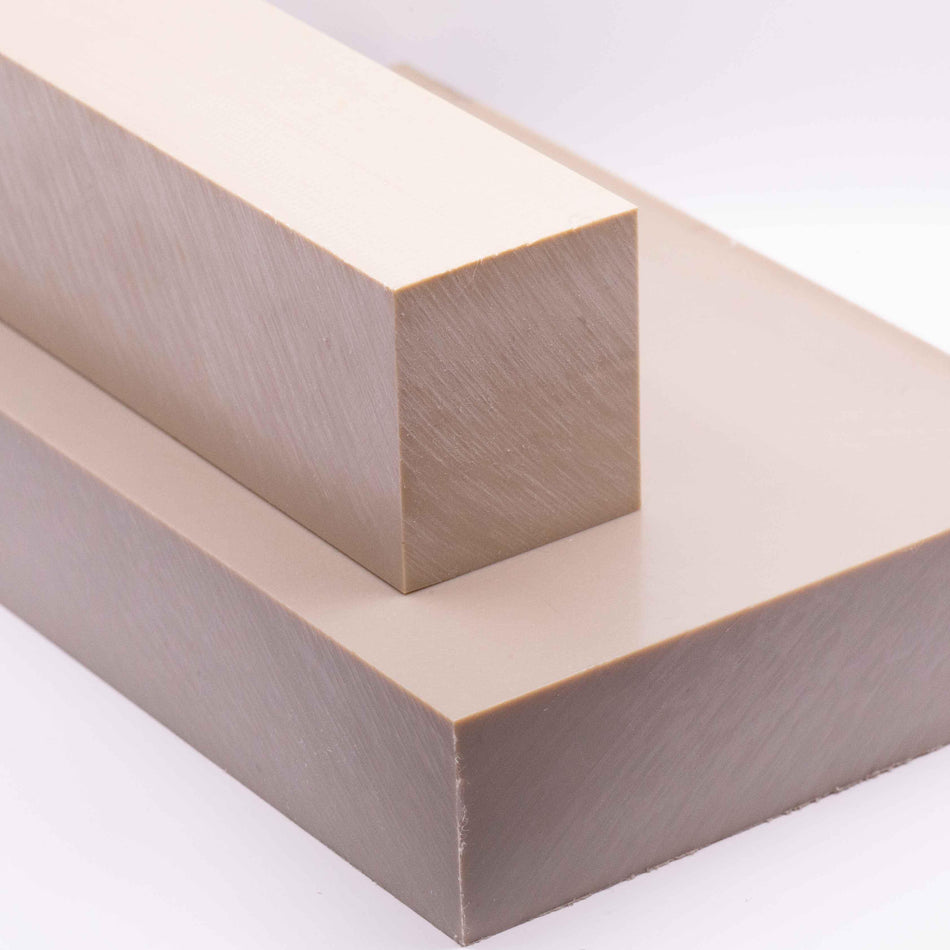

What is PEEK GF30?

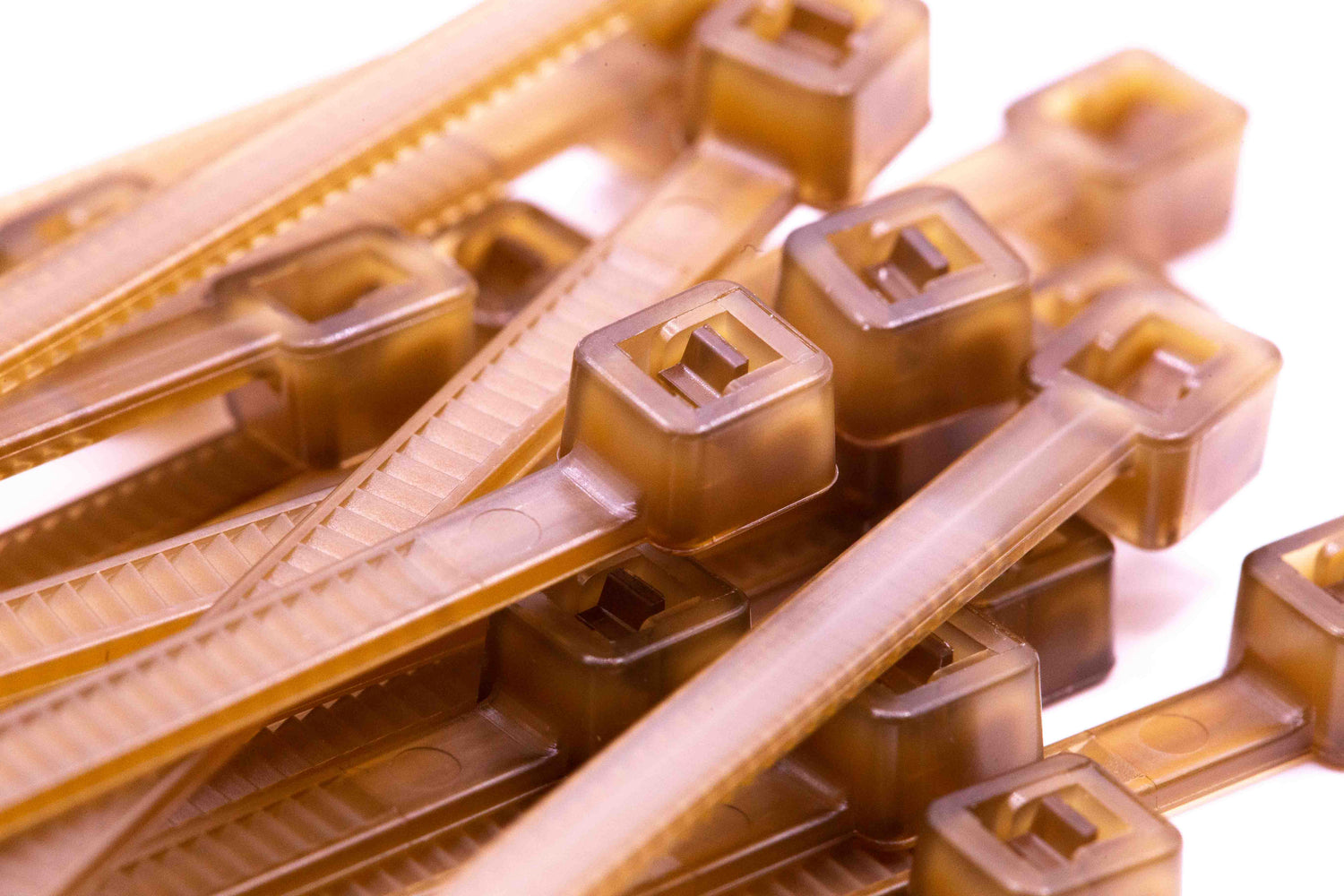

Polyether ether ketone (PEEK) is a high-performance engineering plastic that has many exceptional properties, making it suitable for use in a wide range of applications. A common variation is PEEK GF30, which is unfilled PEEK that has been reinforced with 30% glass fibres. This reinforcement gives PEEK GF30 improved strength and stiffness compared to unfilled PEEK.

PEEK GF30 is a semi-crystalline polymer, which means that it has both crystalline and amorphous regions in its structure. The crystalline regions of PEEK GF30 give it excellent mechanical properties, such as high tensile strength, flexural strength, and modulus of elasticity. The amorphous regions enable high levels of toughness and impact resistance.

The addition of glass fibres further enhances PEEK GF30’s mechanical properties, making a highly suitable material for use in applications where unfilled PEEK doesn’t meet the high strength and stiffness required.

PEEK GF30 - High Tensile Strength

The tensile strength of PEEK GF30 is typically in the range of 150 to 170 MPa. This is significantly higher than the tensile strength of unfilled PEEK, which is typically in the range of 90 to 100 MPa. The addition of glass fibres within GF30 increases its tensile strength significantly, making it the perfect material for use in applications where PEEK is required as well as high strength.

PEEK GF30 is known for its high modulus of elasticity, which is a measure of a material's stiffness. The modulus of elasticity of PEEK GF30 is typically in the range of 3,000 to 4,000 MPa (435,000 to 580,000 psi). This is significantly higher than the modulus of elasticity of unfilled PEEK, which is typically in the range of 1,500 to 2,000 MPa (217,000 to 290,000 psi). The high modulus of elasticity of PEEK GF30 makes it a suitable material for use in applications where stiffness is important.

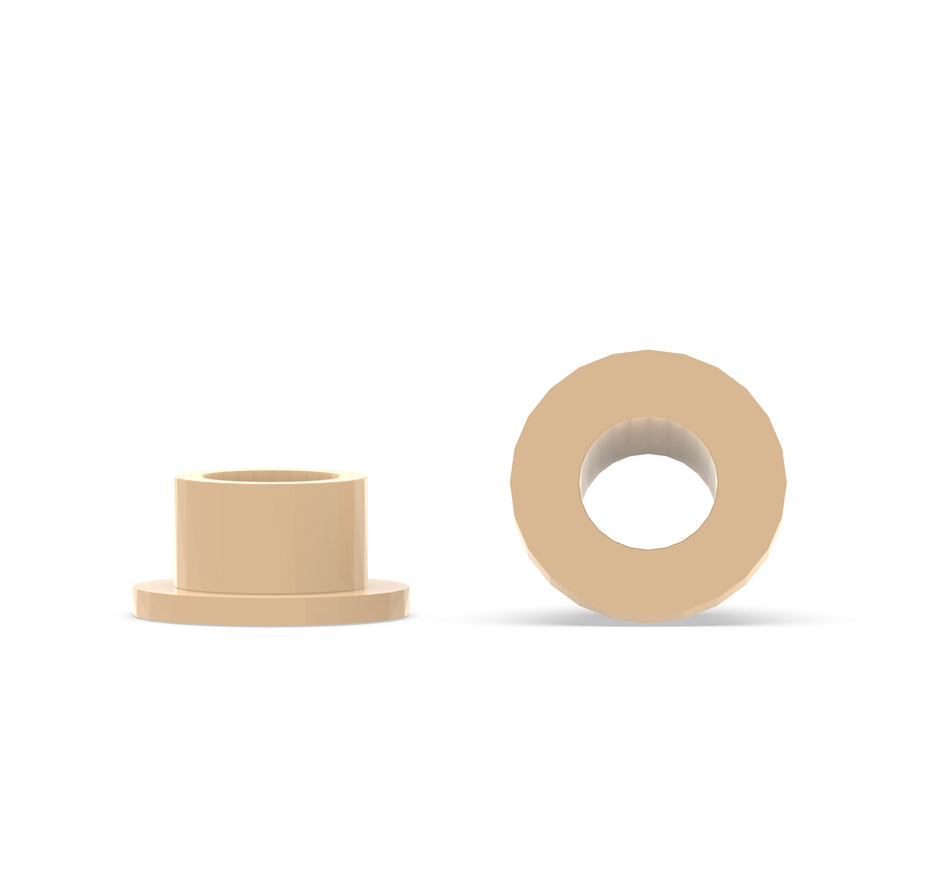

PEEK GF30 Screws, Nuts and Flat Washers

High Performance Polymer offer a range of PEEK GF30 Fasteners. Find out more by selecting a product below:

Key Benefits

-

Thermal stability

One of the main benefits of PEEK GF30 is its excellent thermal stability. It has a high glass transition temperature (Tg), which means that it can withstand high temperatures without losing its mechanical properties. PEEK GF30 can be used at temperatures up to 260°C (500°F) for short periods of time, and up to 180°C (356°F) for extended periods of time. This makes it suitable for use in high-temperature environments, such as in the aerospace, oil and gas, life science and automotive industries.

-

Chemical resistance

Resistant to a wide range of chemicals, PEEK GF30 is suitable for use in corrosive environments. It also has excellent resistance to hydrolysis, making it resistant to swelling when exposed to water and steam. It's also resistant to many organic solvents and has good resistance to oils and fuels.

-

Electrical Insulation

In addition to its excellent mechanical and thermal properties, PEEK GF30 also has good electrical insulation properties. It has a high volume resistivity, making it resistant to electrical current, and it has low dielectric constant and dissipation factor, making it a good insulator. This makes PEEK GF30 suitable for use in electrical and electronic applications where higher strength is required.

-

Bio Compatibility

PEEK GF30 is biocompatible, making it suitable for use in medical applications. It has been used in a variety of medical devices, such as implants, surgical instruments, and drug delivery systems. It is FDA approved for use in the food processing industry, as it is resistant to food acids and is easy to clean.

Summarised Properties of PEEK GF30:

-

Exceptional chemical resistance

PEEK GF30 can only be dissolved in high concentrations of Nitric and Sulphuric acids.

Exceptional dimensional stability

Even at high temperatures (260°).

Low Radio Frequency noise

Comparable to air.

Excellent weight to strength ratio

Specific gravity (1.30). -

- High heat operation (260°C)

- High tensile strength (16Mpa)

- Ultra low weight

- Flame resistance

- Abrasion resistance

- Hydrolysis resistance

-

- Highly resistant to radiation

- Non-Magnetic

- Very low outgassing in high vacuum

- Low thermal conductivity

- Non-Corrosive

- Food safe (FSA/FDA Approved)

PEEK GF30 Datasheet

Our glass-filled PEEK components use GF30 grade PEEK. View our data sheet for more info.